Our Approach

DESIGN. MAKE. BUILD.™

The Process to Unlock Progress

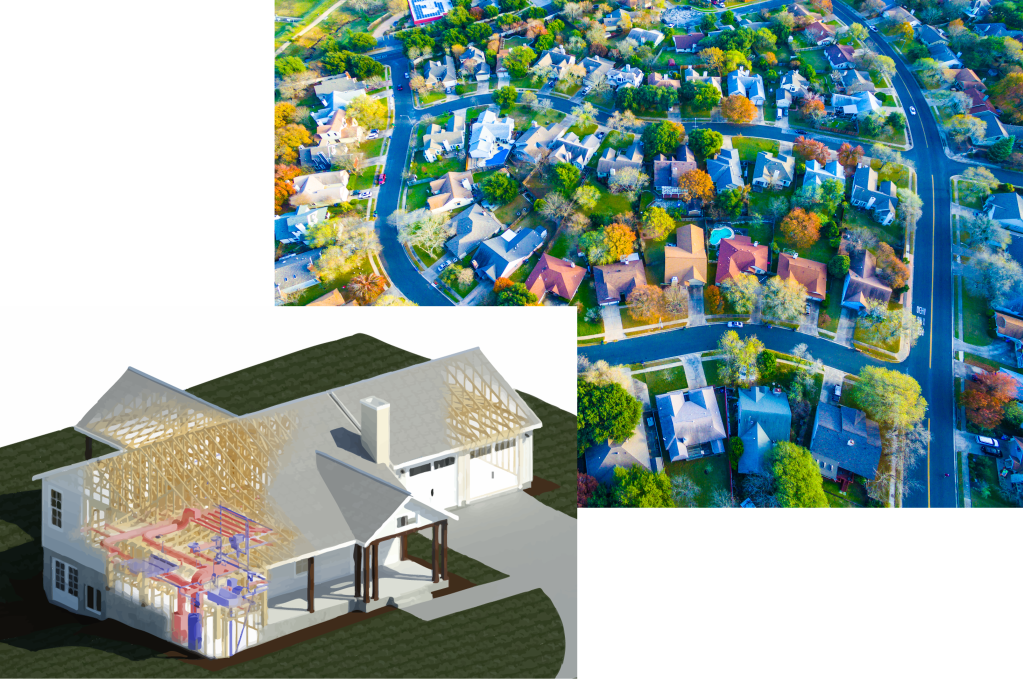

The world has changed a lot over the last 100 years — but not the way we build. And now, the industry faces a growing crisis: explosive demand for housing, workforce shortages, widespread inefficiency, unsustainable waste, and much more.

Off-site construction can help address these challenges — and deliver more value — but first, off-site components must be part of the plan, starting with design.

That’s precisely what Design-Make-Build™ was created to do.

Challenging the Status Quo

Compare the speed of framing two identical houses: one using components from the Design-Make-Build process, and another using the traditional stick-built approach.

The component house is framed three full days before the stick-built house.

See for yourself.

Source: Innovation Build Program, MiTek, 2021, Indianapolis

Phase by Phase Improvement

In the Design-Make-Build process, each phase sets up and improves on the one that follows. Designing with the end in mind allows errors to be fixed virtually rather than in the field.

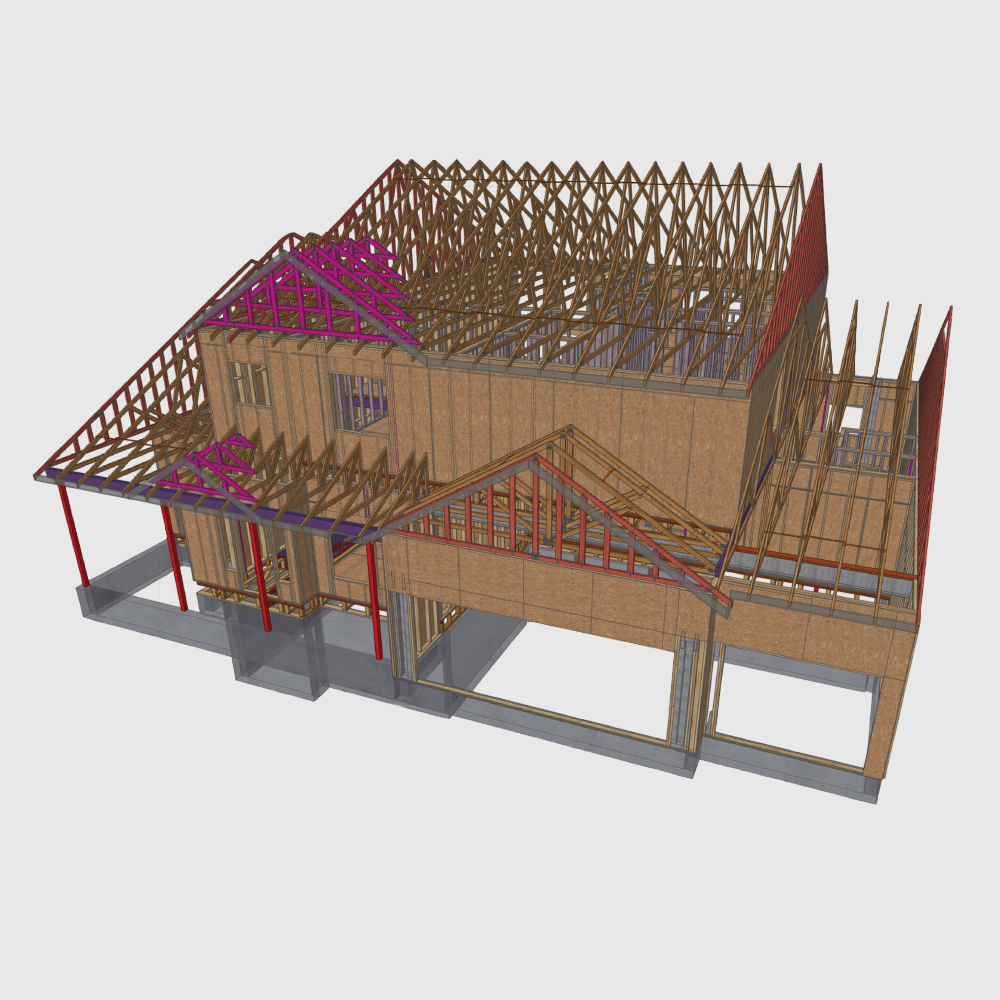

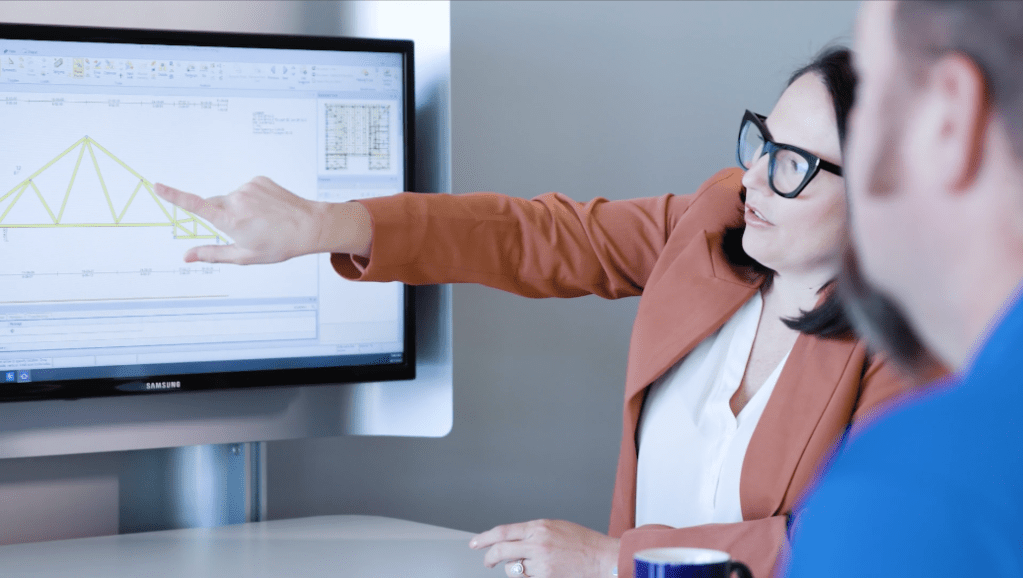

Design

Software and Services enable collaboration across specialities and optimize build plans for off-site construction.

Make

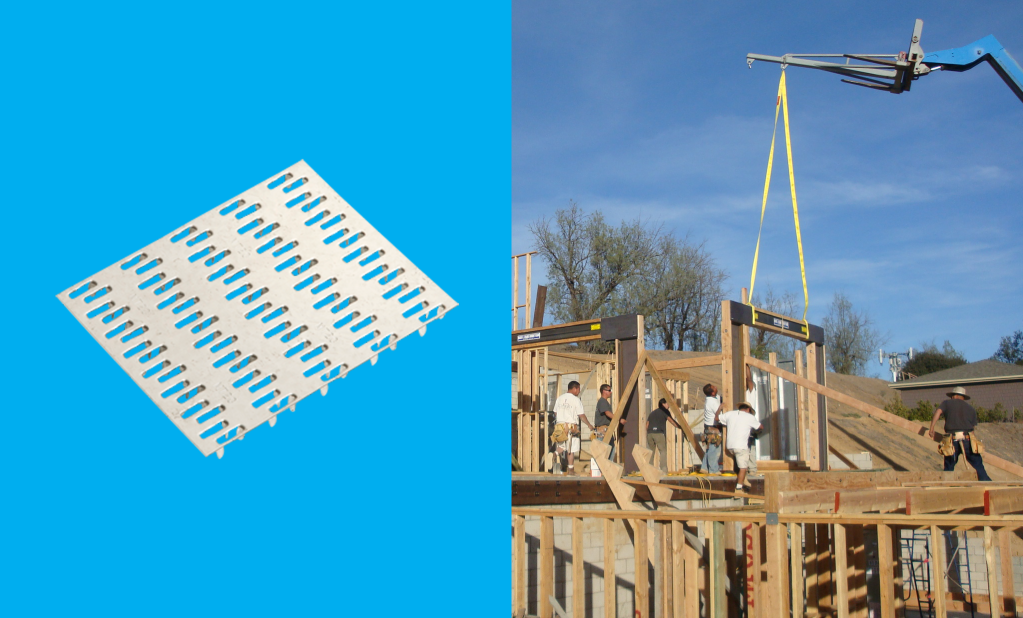

Off-site manufacturing and automation technology empowers the creation of high-quality components at high speed.

Build

Components like roof structures, wall panels, and floor trusses are able to be installed in as little as half the time of stick-built framing.

A Better Way to Build

The Design-Make-Build process and off-site construction enable benefits that conventional construction can’t.

With tightly controlled manufacturing processes and quality checks in off-site factories, best-in-class builders are already achieving defect-free rates that exceed 95% on their projects.

With automated processes, dramatically improved labor efficiency, and a climate-controlled production environment, off-site construction can speed up overall building times by more than a third, in addition to better framing and MEP installation speeds offered by components.

When structures are built more precisely and efficiently, energy consumption, required materials, construction waste, and construction emissions can be cut in half.

In a controlled production environment, there is less risk of injury to workers during construction. And due to higher quality builds, there is less liability for general contractors after construction is complete.

The automated and manual equipment used in off-site construction creates so much efficiency that smaller crews can achieve the same output as bigger teams. Shift work also enables 24/7 production.

The efficiencies created by off-site components and Design-Make-Build unlock new savings, profit and growth potential for the industry while making housing more attainable for end users.

Measuring the Impact of Whole Home Componentized Construction

faster than

traditional framing

less jobsite

waste produced

fewer hangers

required

faster MEP

installation

less wood

product utilized

saved in carrying

costs per home

Sources: Framing the American Dream, SBCA, 2015 & 2024; Innovation Build Program, MiTek, 2023;

Customer Data, MiTek TrueNorth™ Consulting, 2023-2024.

MiTek Offerings

MiTek’s integrated solutions span each phase of the Design-Make-Build process,

giving teams the tools they need to optimize projects and their operations.

Software

Software for component design, engineering, business and process management, HVAC design, and more.

Automated Solutions

Retrieval systems and conveyors for moving lumber. Saws for precise and rapid cutting. Tables with built-in jigs for component assembly, and more.

Engineered Products & Systems

Connector plates for roof and floor trusses. Line of lateral force-resisting solutions covering a spectrum of load conditions. Prefabricated wall panels for building enclosures, and more.

Services

Skilled and degreed professionals ready to handle technical work, respond to demand, and seamlessly integrate with your team and processes. 3D modeling, estimating, component design, and more.

Delivering Value for Everyone

MiTek products and services deliver value across the construction

supply chain.

Are you ready to unlock the power of off-site

components and Design-Make-Build?

Connect with one of our experts to learn more.